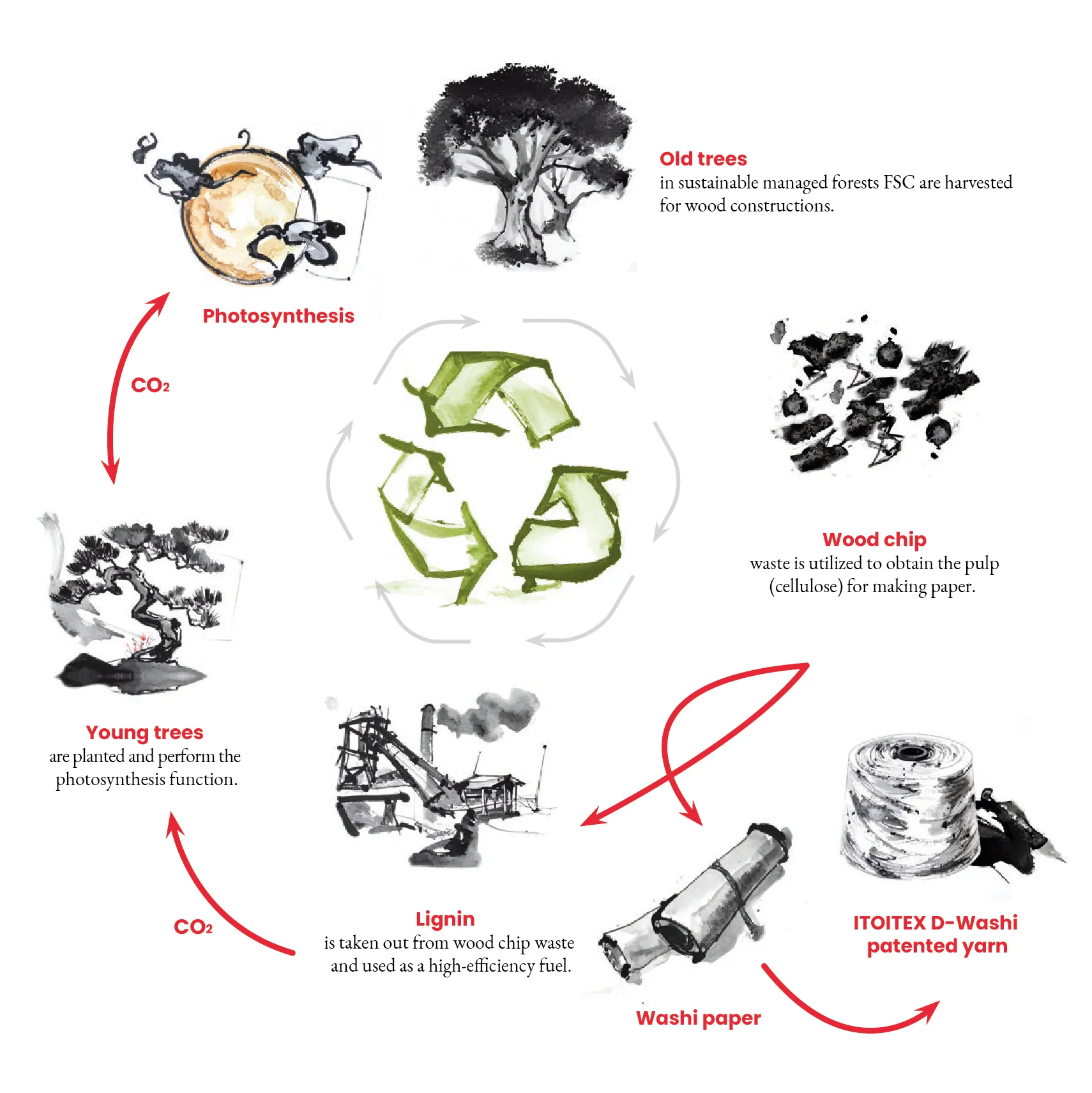

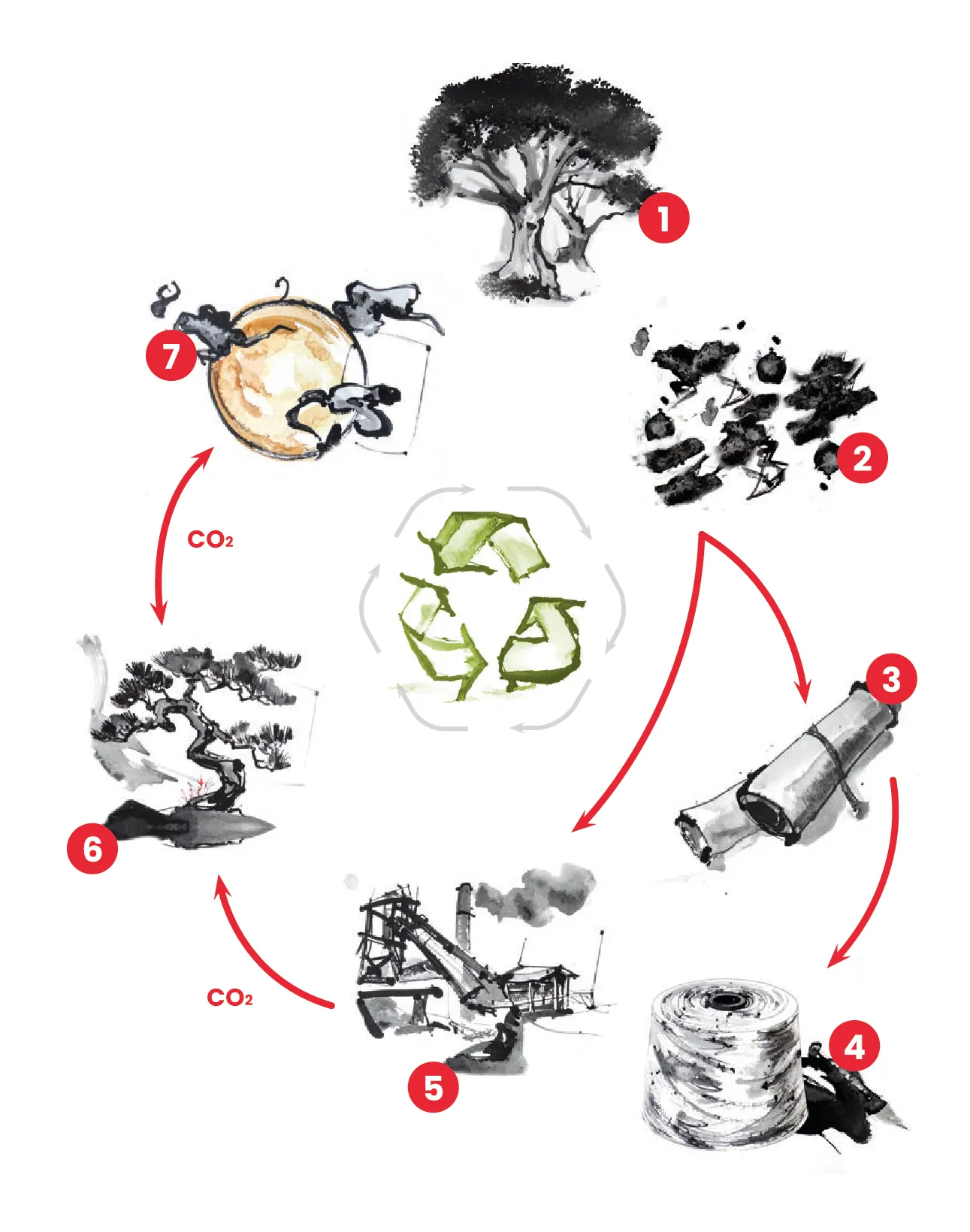

Washi is obtained from the pulp waste of FSC forest conifers. The production of Washi is part of a re-generation cycle, where aged trees are cut and replaced by young ones, able to better perform CO2 absorption.

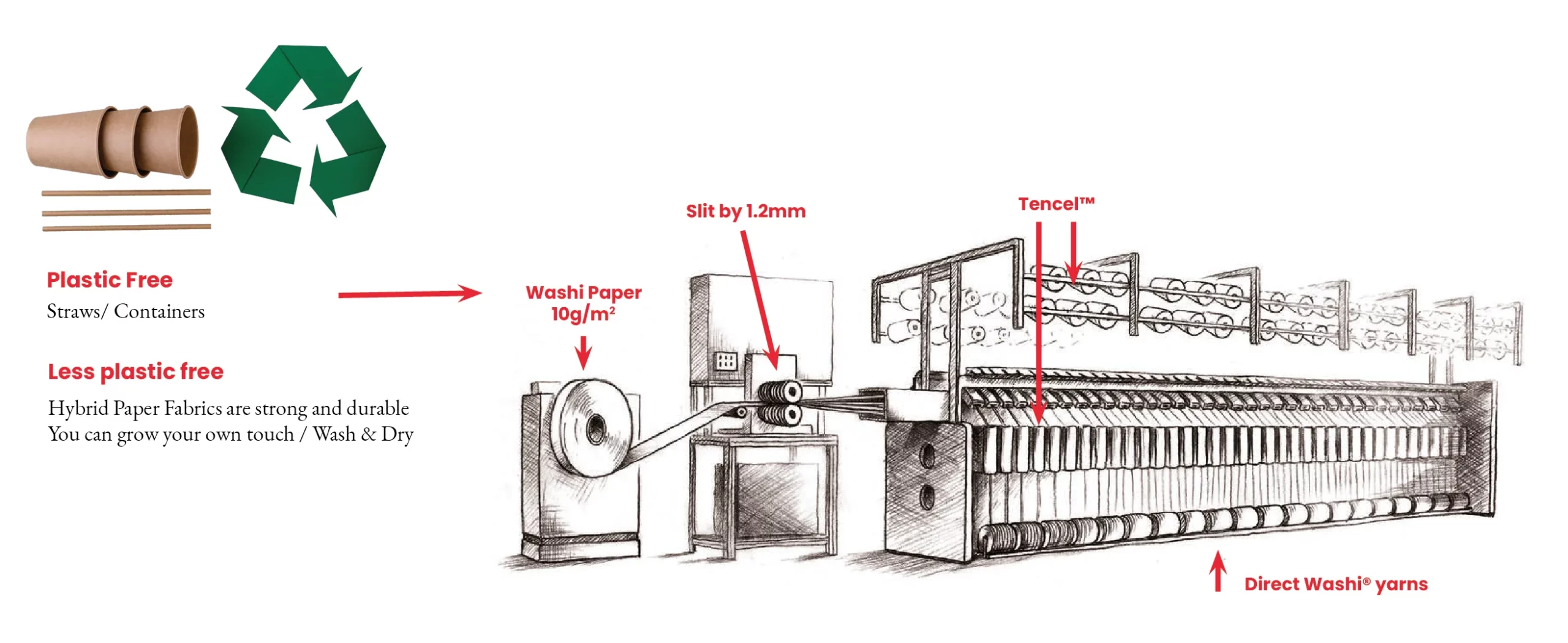

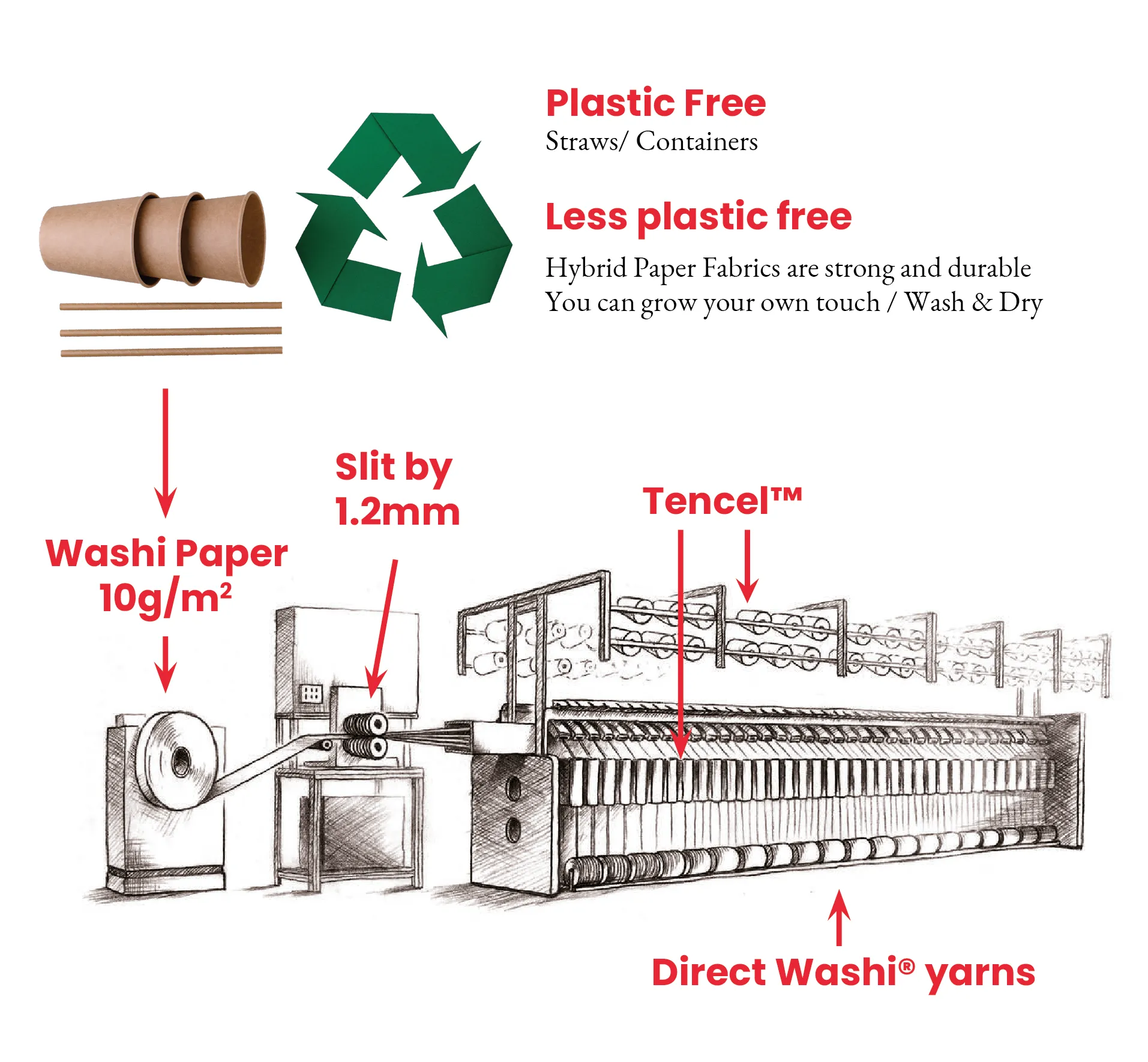

ITOITEX hybrid yarn made from Washi paper is a first quality soft yarn with natural benefits for textile applications.

Woods: from trees

Plants: such as SUSAL, ABACA, BAMBOO etc.

“Trees, the most sustainable

and renewable resource in the world”

in sustainable managed forests FSC are harvested for wood constructions.

waste is utilized to obtain the pulp (cellulose) for making paper.

is taken out from wood chip waste and used as a hight-efficiency fuel.

are planted and perform the photosynthesis function.

Washi thermal conductivity rate is dramatically lower than other materials. Thus, Washi is excellent for Bed-linen, curtains, upholstery, apparel and intimate applications.

Washi is extremely light and sensitive depending on the environment. It immediately reacts like a natural humidity controller.

A yarn with multiple applications

Washi 和紙, literally “Japanese paper”, is a plant- based material, fundamental in Japanese lifestyle.

Since ancient times, Washi is used for the sliding doors due to its thermo-regulating characteristics: it keeps homes cool in summer and warm in winter; it has an excellent moisture control function, it purifies indoor air and filters light. It has many uses: origami, Yen banknotes, art of calligraphy, lampshades…

ITOI LSR Co.,Ltd. textile R&D company, is focused on the development of eco-friendly paper yarns. It is considered a pioneer in the use of Washi in textile.

Washi is the base of ITOITEX products.

What is the strong point of Itoitex?

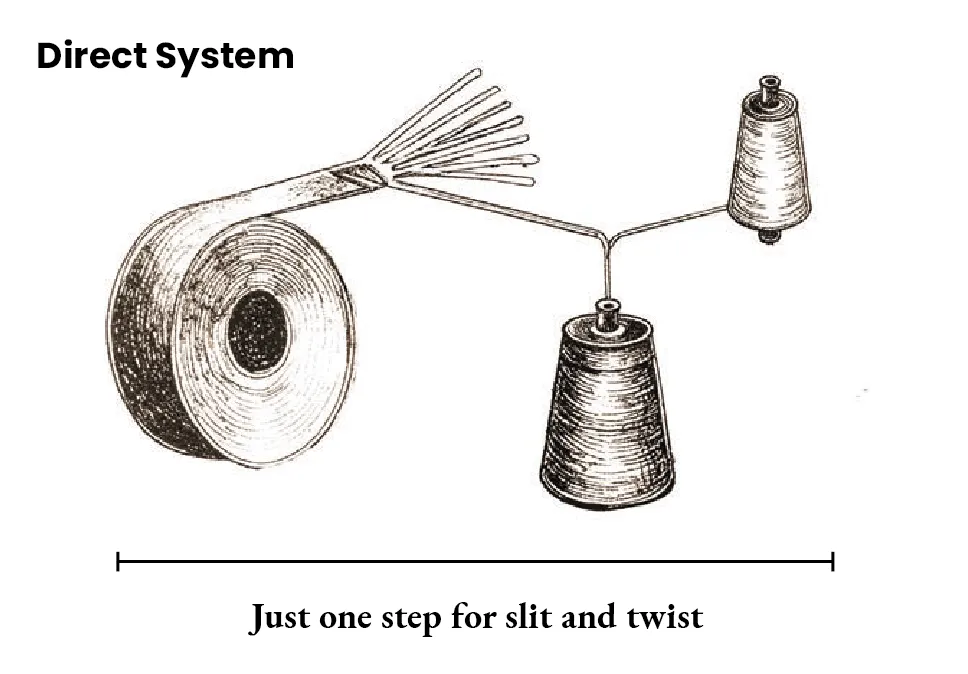

The traditional and conventional method to produce Washi paper yarns had been depended on skilled artisans but Itoitex.

Mr.Toru Itoi invented the patented 1st paper yarn spinning machine in the world, which makes the production sustainable!